Jamie Mayer

Evolution Edges introduced its universal quick change scraper system, or UNIQCS, at the American Public Works Association (APWA) Public Works Expo in Minneapolis.

The UNIQCS, can be installed or replaced without tools and by one person in 20 minutes. The clamp sets are bolted to the moldboard only once when installed, and the polyurethane blade sections are slid off the end when they need to be replaced.

The clip is locked into a clamp to secure the cutting edge, Evolution Edges says, and can be changed from positive to negative blade designs as needed, depending on snow conditions and surface requirements.

The design decreases plow vibration, the company adds, and ultimately reduces driver fatigue.

Carbide Overview-

It is a well known fact that carbide insert snow plow blades provide superior performance in terms of longevity when compared to traditional steel snow plow blades. Life expectancy of carbide blades is generally 10 to 20 times longer than that of a steel blade depending on the steel grade and blade thickness of the steel blade being compared.

With this in mind, it is critical to know that all carbide blades are not the same. Our carbide snow plow blades start with high quality, flat, hot-rolled A36 finished steel that is machined to exacting tolerances for the acceptance of our carbide inserts. When looking at carbide inserts, we specifically designed ours to be superior to all carbide snow plow blades currently on the market. Carbide blade performance will depend on multiple factors including the chemical composition of the carbide inserts, the fit-up between the machined slot in the steel blade and the width of the carbide insert and the brazing process and brazed used to affix the carbide into the steel blade. At Evolution Edges we utilize the latest, technically advanced materials and equipment to ensure our carbide blades are superior in terms of operating performance.

With this in mind, it is critical to know that all carbide blades are not the same. Our carbide snow plow blades start with high quality, flat, hot-rolled A36 finished steel that is machined to exacting tolerances for the acceptance of our carbide inserts. When looking at carbide inserts, we specifically designed ours to be superior to all carbide snow plow blades currently on the market. Carbide blade performance will depend on multiple factors including the chemical composition of the carbide inserts, the fit-up between the machined slot in the steel blade and the width of the carbide insert and the brazing process and brazed used to affix the carbide into the steel blade. At Evolution Edges we utilize the latest, technically advanced materials and equipment to ensure our carbide blades are superior in terms of operating performance.

Carbide Properties

We worked with multiple suppliers of tungsten carbide to develop a specific carbide grade in terms of chemical composition and physical properties that results in superior product performance from a wear and shock resistant perspective.

Carbide Hardfacing In an attempt to simplify a very complex subject, the performance of carbide in a snow plow blade applications will be dependent upon three basic factors, (1) the chemical composition of the carbide (the relationship between the tungsten carbide and cobalt filler), (2) the hardness of the carbide and (3) the grain size and structure of the tungsten carbide. The key characteristics you want to achieve on snow plow applications are hardness for extended life, shock resistance and transverse rupture strength for durability while plowing. By varying the three input variables consisting of tungsten carbide content, cobalt content and tungsten carbide grain structure, you can alter the performance characteristics of the carbide inserts.

Carbide Hardfacing In an attempt to simplify a very complex subject, the performance of carbide in a snow plow blade applications will be dependent upon three basic factors, (1) the chemical composition of the carbide (the relationship between the tungsten carbide and cobalt filler), (2) the hardness of the carbide and (3) the grain size and structure of the tungsten carbide. The key characteristics you want to achieve on snow plow applications are hardness for extended life, shock resistance and transverse rupture strength for durability while plowing. By varying the three input variables consisting of tungsten carbide content, cobalt content and tungsten carbide grain structure, you can alter the performance characteristics of the carbide inserts.

As the tungsten content percentage is increased the hardness of the carbide increases resulting in increased wear life however the carbide becomes more brittle and less shock resistant.

As the cobalt content increases the shock absorption ability improves but the hardness drops resulting in less wear.

By varying the grain structure of the tungsten you can improve the toughness of the carbide in terms of rupture strength.

As a consumer you can judge the performance of the carbide being used for snow plow applications by matching the specifications of suppliers for hardness, cobalt content and transverse rupture strength. Ideally you want a blade that utilizes carbide inserts that have a high hardness, high cobalt content and high transverse rupture strength. At Evolution Edges we have developed a product that leads the market in terms of all three specifications. We have done this be electing to put more money into our carbide inserts to develop a superior performing product.

Tip1: Preparation-

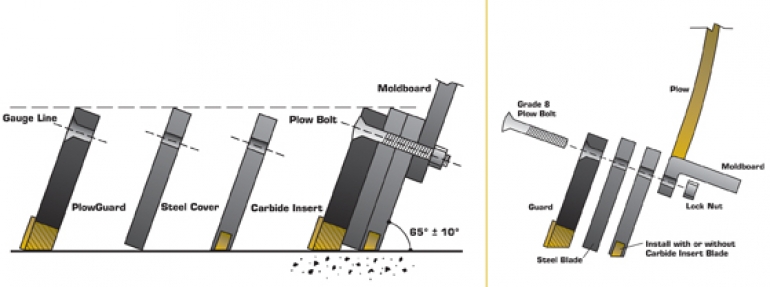

Before attaching the snowplow blade, clean and remove any debris or corrosion from the moldboard that might interfere with a tight assembly.

Tip 2: Repair-

The moldboard acts as the support for the cutting edge. If the moldboard has been shortened from wear and tear, the backward blade torque will be increased, resulting in bolt and blade damage and/or breakage.

Tip 3: Bolts-

Use Grade 8 Plow Bolts- Our Grade 8 heavy-duty domed head design made of alloy steel is proven to have an excellent strength to toughness ratio. With the square neck and counter sunk head design, our bolts will hold your blade firmly in place and distribute the load over a larger area.

To reduce bolt failure and blade chatter, use Number 3 head plow bolts with self-locking nuts.

Tip 4: Nuts-

Use Grade 8 Nuts- Our Grade 8 Nuts are hardened to prevent flattening in use. Lock Nuts lock to the bolt (preferred).

*If using standard Grade 8 nuts, double up!

Tip 5: No Lock Washers-

Lock washers are harder than the moldboard. If used, they will gouge the backside of the snowplow moldboard. These washers act as a cutting tool causing unwanted metal shards on the moldboard, and no matter how hard you tighten the nut, the metal shards will flatten. This causes the nut to loosen and will eventually shave/cut off the bolt. The hardened lock nut will prevent this from happening.

Tip 6: Proper Torque Requirements-

Over-torque- causes heads to pop off. Under-torque shears the bolts due to moving blades during use.